Corrugated Fibreboard

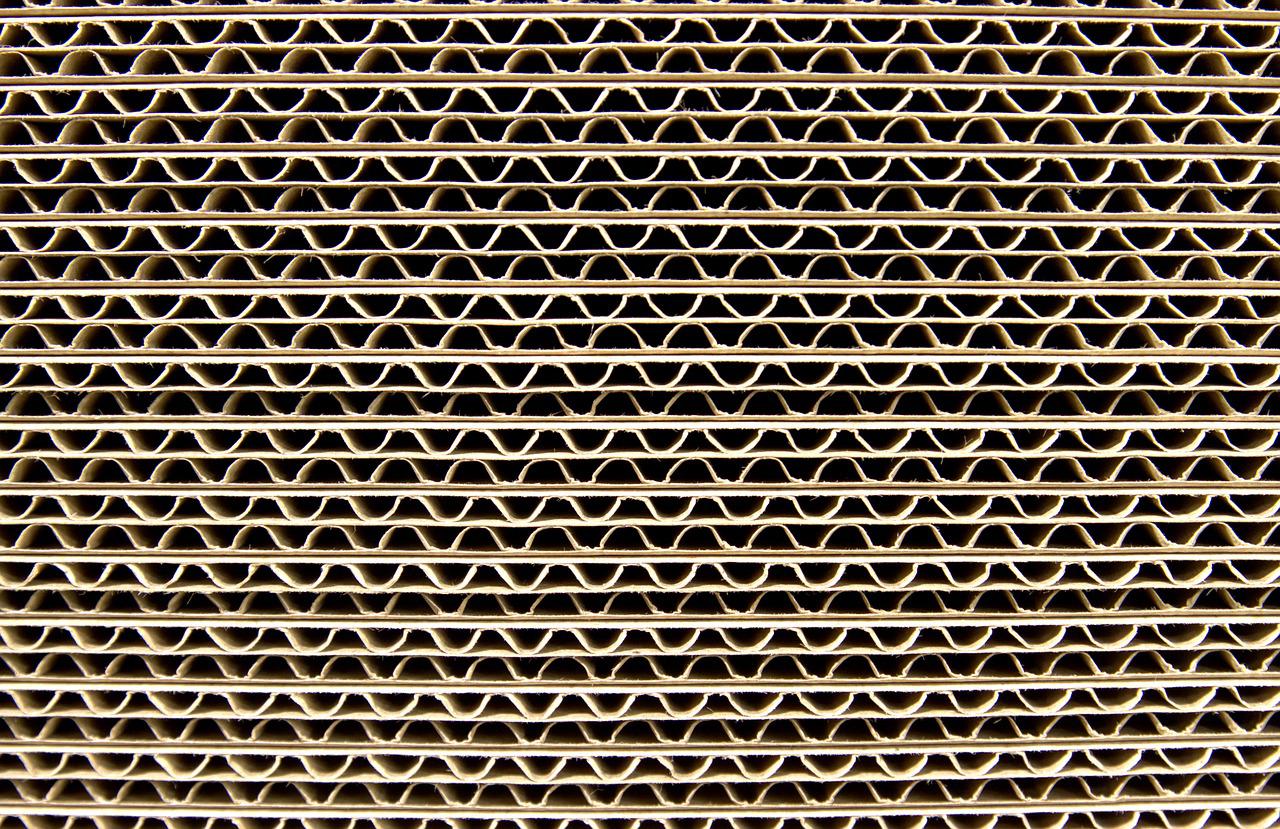

• Material consisting of a fluted corrugated sheet and one or two flat linerboards.

• Corrugated packaging combines structural rigidity with cushioning qualities to protect heavy or fragile contents from damage.

• Old corrugated containers are an excellent source of fiber for recycling

• It is used as a plastic replacement

• Sustainably manufactured from trees and old corrugated containers

• Corrugated packaging combines structural rigidity with cushioning qualities to protect heavy or fragile contents from damage.

• Old corrugated containers are an excellent source of fiber for recycling

• It is used as a plastic replacement

• Sustainably manufactured from trees and old corrugated containers

The flutes are a key to corrugated’s protective qualities. The arches form rigid columns, capable of supporting a great deal of weight while cushioning the container’s contents. The flutes also serve as insulators, providing some product protection from sudden temperature changes.

Corrugated board is manufactured on large high-precision machinery lines called corrugators.

Corrugated fiberboard can be specified by the construction (single face, singlewall, doublewall, etc.), flute size, burst strength, edge crush strength, flat crush, basis weights of components (pounds per thousand square feet, grams per square meter, etc.), surface treatments and coatings, etc.

The key raw material in corrugating is paper, different grades for each layer making up the corrugated box.

Corrugated are frequently manufactured using high percentages of secondary fiber (including old corrugated containers, kraftpaper, old newspapers and even straw) thereby diverting these materials from the municipal solid waste stream.