SBSEnviro Aqua Concepts Private Limited

Year Of Establishment 2006 | sbsenviro.com

SBSEnviro is a leading innovative & high-tech products manufacturer for wastewater treatment industry. SBSEnviro is engaged in developing and supplying a range of wastewater treatment equipments. The team comprises of professionals with over 25 years of hardcore experience in water and wastewater treatment technologies and solutions.

ABOUT

The company was established in 2006 by Mr. DS Srinivas Rao and Mr. Pawan Chhabra with its corporate office located at Navi Mumbai. Within a very short period of 12 months, SBSEnviro was able to establish its products in the Indian market and achieve 100 installations in the first year itself, soon expanding its operations all over India, and other parts of Asia, Middle East and Africa. Since then, the company is surging ahead with the sole mission to offer innovative, eco friendly and energy conserving technologies and products for all applications related to the treatment of Water & Wastewater.

The one stop shop for wastewater management.

Srinivas Rao

Managing Director

Pawan Chhabra

Director

OFFERINGS

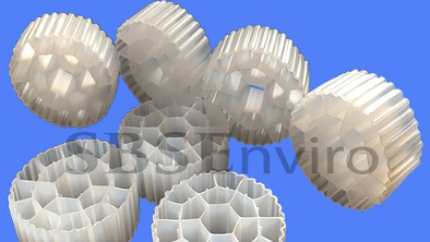

MBBR Bio Media

Driven by air bubbles supplied inside the reactor by means on air diffusers. BF-22 Random Media provides large surface area for bacterial growth takes place over entire area of the media which overcome the problems faced with conventional moving media.

Disc Diffuser

SBSEnviro, supplies a world class Raubioxon Plus & Raubioflex tubular & disc aerators for maximum oxygen utilization. Air diffusers are of Silicone & EPDM membranes on a Poly Propylene (PP) non-buoyant tube. Its Aeration efficiency is as high as 4.5-5.0 kg/kWh.

Diffused Aeration System (DAS)

Tubular & Disc Diffusers with SILICONE and EPDM based membrane of higher Oxygen Transfer Efficiencies with energy savings of 30-35% in comparison Jet Aerators & 50% on surface aerator / floating aerators applicable in different treatment systems like MBBR, SBR, SAFF, Super Saf, Extended Aeration Process etc.

Aspirator Type Aerators

Fine bubble aeration made of stainless steel AISI 304 draws atmospheric air through its hollow shaft and discharge the water by the rotating propeller of higher aeration efficiency and mixing capability. Application in Aeration/ Activated Sludge Tank, Aerated Lagoons, Aeration in Equalization Tank.

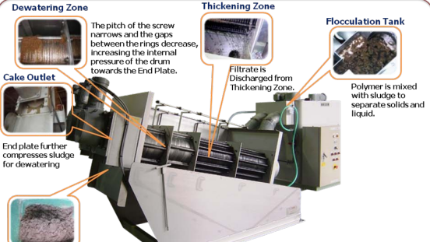

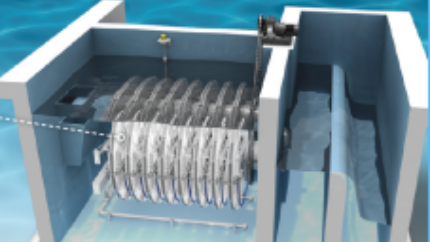

VOLUTE

Volute is a 4th generation sludge dewatering unit, 24X7 machine with auto operational and clog-free design for dewater biological and chemical sludge on wide range of incoming solid concentration from 2000mg/l to 70000mg/l. Machine is available for dry sludge (DS) output of 1.0kg/hr to 750kg/hr.

SeVAMI® Dissolved Air Flotation (DAF)

SeVAMI-DAF designed for removal/recovery of solids, fat, oil, grease from wastewater and process water. Solid rises to the surface of water due to increase in their density which is heavier than water also get attached with air bubbles and get removed.

Multi-stage Centrifugal Blower

Based on the technology of welding multistage low speed centrifugal is a new generation high-efficiency product, operates effectively and efficiently with very little daily supervision or maintenance.

Tri-lobe Blower

Tri-lobe technology means blowers have lobe tips exposed to 120 degrees around the rotor instead of 180 degrees as in a bi-lobe blower. Reduced noise, reduced pulsations and vibrations, longer bearing life and minimal maintenance in mind.

Anti Scale & Rust Pellets

These pellets are a New Japanese technology that enables them to alter the nature of hardness causing minerals including those of calcium and magnesium into tiny soft colloids. Used in wide range of application including Cooling Tower, RO Feed, Boilers feed etc. Lifespan ranges around 5-10 years.

Cavity Media

Superior High Surface area carrier media for high rate MBBR with Zero-Clogging Technology and a huge active surface area. They are fitted with SS-304 retention screen and diffused aeration system.

Disc Filter

Pile Cloth Disk Filter (SBS Disk Filter) is a tertiary treatment filter that removes Suspended Solid and Total Phosphorus. It is a 24-hour continuous operating filter that can remove organic matter, phosphorus and color in conjunction with a chemical pretreatment.

Sludge Dryer

The belt drying is the most suitable sludge drying technology from the Indian point of view considering the overall techno-commercial viability of the product. It requires lesser footprint when compared to other type of dryers. Belt sludge dryers are energy efficient solutions and can be tailor made to suit various sludge drying applications.

• Revamping & Upgradation of ETP

Re-engineering / retrofitting & revamping of existing, effluent treatment plant & anaerobic system are done to new environmental legislation, to reduce OPEX cost by having advanced technology, process improvements, corporate sustainability, additional nutrients removal.

• Operation & Maintenance of ETP

O&M are handled by experienced industry professionals who ensure optimum plant operation and maintenance standards are maintained at all levels. Works on well-defined approach, the team also ensures that effluent treatment plants provide for effective support in BOD reduction, aeration, clarification among others.